Custom Springs

We are ready to take on any challenge!

From large springs to small springs, here we introduce our springs that never fail to live up to expectations.

- Tokai Spring HOME

- Custom Springs

- i-MC SPRING

i-MC Spring

High-quality disc springs that are durable, compact and have high-speed rotation

Features Of Our Springs

The dimensional accuracy and concentricity of disc springs specified by DIN and JIS are not designed in the optimum conditions for rotating applications.Our i-MC SPRING series, on the other hand, was developed as disc springs for machining center spindles, ensuring dimensional accuracy and concentricity suitable for high-speed rotation of 10,000 rpm or more and delivering excellent performance. We also only offer the finest materials to provide highly durable products.

High-Speed Rotation, Long Service Life, and Compactness

Our i-MC SPRING series is a lineup of products that can meet various customer needs, starting with our flagship model i-MC COMPACT. Furthermore, in order to meet the high-level requirements of our clients, we also perform durability evaluations under various conditions using an endurance testing machine that plays the role of the actual machine for which the springs will be used.

Key Points on Our Devotion to Handmade Springs

In order for our clients with machining center spindle applications to use high-quality products without hassle, our i-MC SPRING series is guaranteed to meet the required load characteristics in a combined state, and to provide your ordered springs in such a way that you have to embed them once they arrive. Our disc springs are perfect for the sliding wear of spindles and load control of rotating parts!

The ultimate disc springs for main spindles

Our i-MC spring series has gained a high reputation as disc springs for main spindles on machining centers among manufacturers who can have absolute trust in them.

i-MC COMPACT is a new and innovative product of the i-MC spring series.Long service life, compactness and balanced performance.

Thanks to these innovative improvements, this new product achieves the ideal form of disc springs for the main spindles on machining centers.

1.Four outstanding characteristics

1-1 Longer lifespan

|

The i-MC COMPACT achieved product lifespan at least three times |

|---|

1-2 Compact design

|

More than 50% smaller in size of i-MC COMPACT compared with |

|---|

1-3 Balanced performance

|

The i-MC COMPACT can support ultra-high-speed rotation with |

|---|

1-4 Wide range of adoption

|

Since the launch of the i-MC COMPACT five years ago, |

|---|

2. i-MC compact’s characteristics compared to other products

2-1 Service life

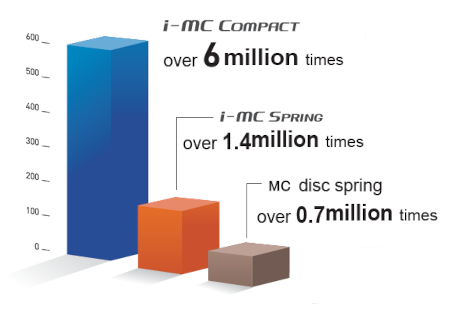

Remarkable long lifespan of i-MC COMPACT

|

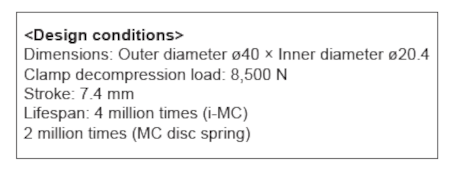

The figure on the left compares the design |

|---|

2-2 Compactness

Significant space saving through compact design

|

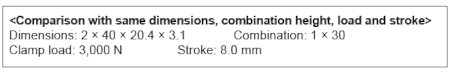

More than 50% smaller in size of i-MC COMPACT |

|---|

2-3 Balanced performance

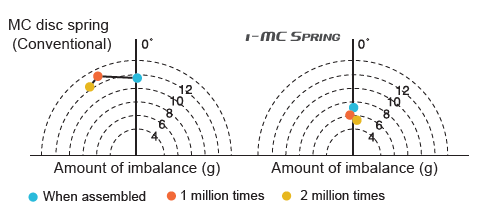

Excellent balanced performance at ultra-high speed rotation

The i-MC COMPACT demonstrates excellent balanced performance on high performance machining centers that require ultra-high-speed rotation. The amount of imbalance is reduced to around 65% that of the conventional Tokai Spring disc springs for machining centers (the MC disc springs). In addition, even after 2 million usages the balance characteristic of the spring remains mostly unaltered.

* This data is a comparative measurement of the amount of imbalance on just the disc springs + spindle. It is not the amount of imbalance of the entire unit, which combines a motor, etc.

2-4 Damping avoidance

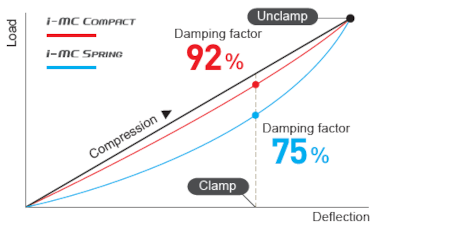

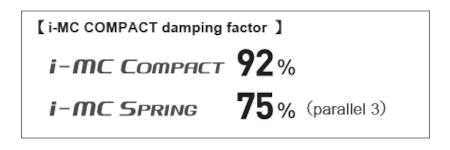

Thorough elimination of damping during clamping

|

The i-MC COMPACT eliminates the load damping |

|---|

Complete R&D support system

Testing equipment that replicates the operational environments as close as possible

Fatigue testing equipment

Investigating the mechanisms of breakage

There were cases that a disc spring that did not break in repeated testing on general spring fatigue testing equipment easily broke in real working situations.

We identified that the mechanisms and operations applied in a fatigue testing equipment were significantly different compared with the actual conditions inside a machining center. To solve this problem, Tokai Spring developed and installed dedicated fatigue testing equipment that replicate the actual operational environments inside the main spindles of machining centers.

This made it possible to investigate the true mechanisms of disc spring breakage in the main spindles on machining centers. Based on this analysis, we developed a system to evaluate the effectiveness of countermeasures against the potential breakage.

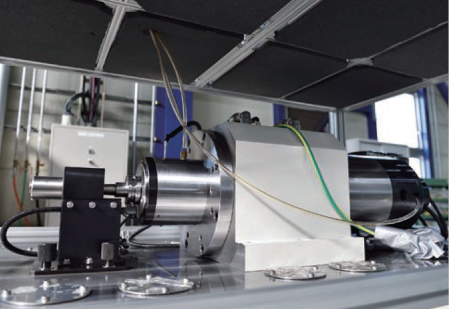

High-speed rotation testing equipment

Complete replication of the high speed rotation and compression operations

The disc springs in the main spindles on machining centers are not only subjected to repeated compression operations but also high speed rotation. It was assumed that the rotation operation will not affect the lifespan or performance of the disc springs. However, we assumed that movement of the lubrication grease due to the centrifugal force resulting from the rotation would have had an effect on the disc spring performance and/or lifespan of the disc springs. With this assumption, Tokai Spring developed and installed a dedicated disc spring fatigue testing equipment that can replicate the actual rotation operation (MAX 20,000 min-1).

This equipment enabled us to test disc springs replicating the actual high speed rotation and compression in real work situations.

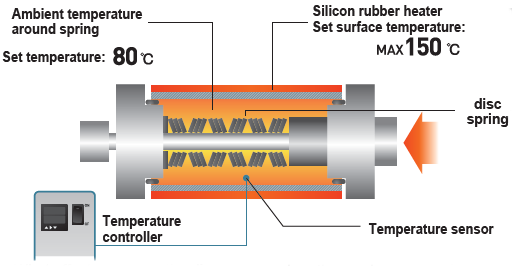

Fatigue testing equipment in special working environments

Fatigue testing under the high temperature environment

What effects occur on the disc springs when the inside of the main spindle of a machining center reaches a high temperature? What response measure should be taken in that case? To solve issues such as these, Tokai Spring can implement fatigue testing with reproduction of the high temperature environment. We then make proposals that accurately describe those effects and their countermeasures.

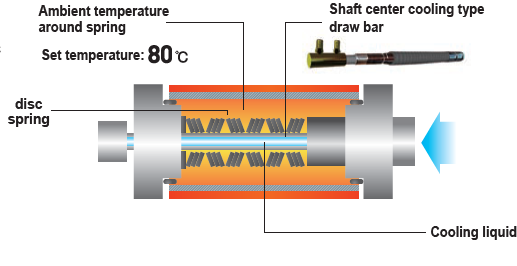

Fatigue testing under the condensation environment

How are disc springs affected by the condensation that forms inside the main spindle of a machining center? This was also a big question.

Tokai Spring can also implement fatigue testing that reproduces this condensation environment.

Proposals can be made for any assumed conditions.

R&D improvements of grease for drawbars

Surface treatment on draw bar

A draw bar is an integral part to be used with disc springs. The quality and surface treatment of the bar has a significant effect on the disc spring performance. What is the optimal surface treatment of draw bars? Tokai Spring applied its accumulated data of its fatigue testing to identify the most effective surface treatment of the bar. We propose the surface

treatment for draw bars that will maximize the i-MC performance.

Comparative testing of grease

Another important factor in disc spring performance is a selection of the grease to lubricate disc springs.

What is the optimal grease to be used inside the main spindle of a machining center? We propose the optimal grease based on the knowhow we have obtained through repeated comparative tests on each product.

Research specifically about machining centers to achieve even longer life

As part of our efforts to create a long service life for these springs, we are also conducting daily research on drawbars with springs inserted.Even though a cylindrical rod profile is seen as obvious choice, Tokai Spring thought there were potential improvements. We found from testing that there is a possibility of dramatically improving the lifespan of disc springs by using draw bars with special cross-sections that are not circular. We have a belief that there is a potential to increase lifespan of disc springs. Tokai Spring will keep working to achieve this goal. Please wait for the news!

-

- We support design and production even for small lots of one or two springs

- In the spring industry, our “complete custom-made production & high-mix, low-volume manufacturing” is an extremely unique production system which has not changed since our founding.

We guarantee to deliver the quantity you need, when you need it, at high quality.

-

- We support all kinds of environments with the likes of heat resistance, corrosion resistance, and durability

- Springs are very sensitive to high and low temperatures and corrosive atmospheres such as rust. Tokai Spring conducts daily verification tests to properly maintain the performance of our springs in any environment such as at temperatures of 100°C or higher, -20°C or lower, as well as for applications in which our springs are exposed to seawater or industrial water!