Custom Springs

We are ready to take on any challenge!

From large springs to small springs, here we introduce our springs that never fail to live up to expectations.

- Tokai Spring HOME

- Custom Springs

- Compression Springs

Compression Springs

The coil spring is our most popular spring!

Features of Our Springs

The most popular spring in the world, the compression springs boasts a simple shape.

The compression springs can be manufactured at a lower cost than other springs.

Larger sized compression springs are also called hot-formed compression springs because the material is heated to a high temperature of at least 800°C to form it. It supports several tens of tons as its maximum load. Small compression springs, on the other hand, are formed at room temperature, and so they are called cold-formed compression springs.

We can manufacture a material diameter of up to 90 mm, a coil outer diameter of up to 600 mm, and a free length of up to 1,200 mm!

A Giant Spring-Forming Machine - One of Its Kind in the World

- A Giant Spring-Forming Machine

- One of Its Kind in the World “YUKI”

A Giant Spring-Forming Machine - One of Its Kind in the World

The super-coiling machine, “YUKI”, is the only large spring-coiling machine of its kind anywhere in the world. It is packed with the experience and know-how of our artisans that have been accumulated over many years. Especially for heavy-duty compression springs that use large diameter materials and long materials, for which it is said to be difficult to maintain their quality during coiling, the birth of YUKI, which can control 6 axes simultaneously, has made it possible to achieve highly accurate spring characteristics and to be able to support even single spring orders.

Key Points on Our Devotion to Custom Compression Springs

-

- Winding

- Winding is performed by hand by the artisan who carefully examines the characteristics of materials that have high strength, high heat resistance, and high durability.

-

- Polishing

- In the case of small compression springs, their squareness and parallelism will change by applying a slight amount of force. Producing a beautiful washer for a delicate spring while satisfying the conditions is a difficult technique that truly puts the skills our a craftsmen to the test.

-

- Tuning

- Pitch adjustment greatly affects the characteristics of the spring. In this important process that determines the characteristics of the spring, we carefully finish each and every spring to highly accurate dimensions and shapes.

Key Points on Our Devotion to Custom Heavy-duty Compression Springs

-

- Coiling

- The material is put it into an induction heating furnace, heated up quickly to around 900℃, and then coiled.

-

- Heat Treatment

- This process is also called “Breathe a life into the spring”. In the spring making process, this is said to be the most important stage. There are two processes in heat treatment: quenching and tempering.

-

- Adjustment

- After heat treatment is finished, spring undergoes the adjustment process.

This process is conducted using this device. Here, the spring is loaded for the first time, to actively exhibiting initial setting.

Another Key Process for Producing High Quality Compression Springs

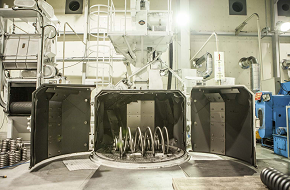

A Shot Peening Machine

Metal fatigue is the effect of the formation of cracks in stress-concentrated parts of metal material to which repeated load is applied; when progressed, this effect leads to the destruction of the material. This phenomenon may also occur in springs.

However, by applying the shot peening, we can significantly improve fatigue strength. Shot peening is the process of striking the spring surface with round iron balls (media) at high speed. The spring is placed in the machine as shown in the picture and undergoes the shot peening process. This makes our springs suitable for reliable usage for a long time. There are a lot of other effects of the shot peening to springs too.

Features of Tokai Spring's coil springs

A wide variety of materials

The material diameter of springs ranges from 0.3mm to a maximum of 90mm, and the maximum length of material is 14m700mm. We always have 400 tons of materials available for use in a variety of environments. With this abundance of materials, we are always ready to meet any request from our customers.

Shape control

We insist on high shape accuracy even for a single spring. We use our own manufacturing technology to make springs with a precision that exceeds the general JIS tolerance, so that even the "bowing" of the spring, which does not appear on the drawings, is very small. In order to pursue quality and precision to the utmost, we also have hundreds of core wires that are wound into the shape of a spring, in millimeter increments. The craftsmen who operate them select the most suitable core wire for each shape and wind the spring. We also aim to make springs that fully bring out the performance of the customer's own products by, for example, changing the degree of polishing of the spring end planes according to the application.

Load control

We specialize in producing coil springs that achieve highly precise load conditions. While there are tolerances for "deflection" and "load" when a coil spring is compressed, Tokai Spring Kogyo has established its own in-house tolerances that are the strictest in the industry, ensuring the load accuracy required for important applications. Moreover, when a coil spring is compressed in the axial line, there is always a phenomenon where the load escapes in the lateral direction. To minimize this phenomenon to zero, we use a transverse load test machine developed by our own company to measure and adjust the load, resulting in springs that function with utmost accuracy and precision.

Long life and sagging resistance

We strive to make springs that have excellent "fatigue resistance" and meet our customers' requirements for "long life without breakage" and "long-term sagging resistance." To achieve this, we adopt a heating method that minimizes the decarburization layer on the material surface, apply compressive residual stresses through shot peening, and remove any small scratches on the spring surface. Additionally, we conduct static plastic deformation tests and dynamic fatigue tests to evaluate the sagging and durability of spring holders during the prototype production stage. With these comprehensive systems, Tokai Spring is able to provide springs that can be confidently used for extended periods of time.

-

- We support design and production even for small lots of one or two springs

- In the spring industry, our “complete custom-made production & high-mix, low-volume manufacturing” is an extremely unique production system which has not changed since our founding.

We guarantee to deliver the quantity you need, when you need it, at high quality.

-

- We support all kinds of environments with the likes of heat resistance, corrosion resistance, and durability

- Springs are very sensitive to high and low temperatures and corrosive atmospheres such as rust. Tokai Spring conducts daily verification tests to properly maintain the performance of our springs in any environment such as at temperatures of 100°C or higher, -20°C or lower, as well as for applications in which our springs are exposed to seawater or industrial water!

Specifications for Our Compression Springs

Compression Springs for Safety Valve Specifications

| Spec category | Item | Specification | |

|---|---|---|---|

| Standard specifications | Load characteristics | Load | Max. 30 ton |

| Load allowance | Standard ±5% as installed and at max. | ||

| Travel allowance | Standard ±5% as installed and at max. | ||

| Spring constant allowance | Standard ±5% at 30∼70% of travel | ||

| Dimensions | D/d | 3.0∼15.0 | |

| H/D | 0.5∼4.0 | ||

| Free length allowance | Standard±1.0% | ||

| Coil diameter allowance | Standard±1.0% | ||

| Perpendicularity allowance | 1.0% of free length | ||

| Durability | Standard durability improvement processing | Shot peening | |

| Service-life | Standard service-life: 10 years | ||

| Material | SUP10(Correspond to 51CrV4,6150) Chrome-Vanadium steel for spring | Wire diameter: φ13∼25 Material length: 8m | |

| Wire diameter: φ26∼90 Material length:12m | |||

| Conditions of use | Indoor working temperature | -50∼180℃*1 | |

| Rustproofing | Standard | Coated with anti-rust oil | |

| Coated with black powder (Polyester resin) | |||

| Electrodeposited black coating | |||

| Dacrotized finish | |||

| Disgo plating | |||

| Custom specifications | Material | Specifications by material | SUP10(Correspond to 51CrV4,6150) Wire diameter: φ26∼90:Material length: 14.7m |

| Load characteristics | Spring axis perpendicular load control | Max. measured load perpendicular to spring axis: 1ton (Max. axial load during measurement: 20ton) | |

| Dimensions | Spring axis perpendicular displacement control | Max. measured displacement: 20mm | |

| Durability | Material surface improvement/Anti-settling improvement | Service-life: 30years | |

- *1:Product allowable stress varies according to temperature. For more information, speak with a Tokai Spring industries engineer.

Compression Springs for Static Actuator Specifications

| Spec category | Item | Specification | |

|---|---|---|---|

| Standard specifications | Load characteristics | Load | Max. 30ton |

| Load allowance | Standard ±10% as installed and at max. | ||

| Travel allowance | Standard ±10% as installed and at max. | ||

| Dimensions | D/d | 3.0∼15.0 | |

| H/D | 0.5∼6.0 | ||

| Free length allowance | Standard ±2.0% | ||

| Coil diameter allowance | Standard ±1.5% | ||

| Perpendicularity allowance | Standard 1° | ||

| Buckling | 1.5% of free length at H/D 4.0 and less | ||

| Durability | Standard durability improvement processing | Shot peening | |

| Durability | Static(1000 or less loading cycles) | ||

| Material | SUP10(Correspond to 51CrV4,6150) Chrome-Vanadium steel for spring | Wire diameter: φ13∼25 Material length: 8 m | |

| Wire diameter: φ26∼90 Material length: 12 m | |||

| Conditions of use | Indoor working temperature | -50∼180℃*1 | |

| Rustproofing | Standard | Coated with anti-rust oil | |

| Coated with black powder (Polyester resin) | |||

| Electrodeposited black coating | |||

| Dacrotized finish | |||

| Disgo plating | |||

| Standard specifications for combination springs | Combined load characteristics | Load | Max. 60ton |

| Load allowance | Standard ±10% as installed and at max. | ||

| Travel allowance | Standard ±10% as installed and at max. | ||

| Dimensions | Best combination | Joining position marking | |

| Custom specifications | Material | Specifications by material | SUP10(Correspond to 51CrV4,6150), Wire diameter: φ26∼90, Material length: 14.7m |

| Durability | Material surface improvement | Hot-rolled skin removal | |

- *1:Product allowable stress varies according to temperature. For more information, speak with a Tokai Spring industries engineer.

Push-pull springs for tuned mass damper

| Spec category | Item | Specification | |

|---|---|---|---|

| Standardspecifications | Load characteristics | Load | Max. 15 ton |

| Load allowance | Standard ±10% as installed and at max. | ||

| Stroke | Max. ±200 mm | ||

| Spring constant allowance | Standard ±10% | ||

| Max. measured length: | 1100 mm | ||

| Dimensions | D/d | 5.0∼15.0 | |

| H/D | Max. 2.5 | ||

| Free length allowance | Standard ±2.0% | ||

| Coil diameter allowance | Standard ±1.5% | ||

| Durability | Standard durability improvement processing | Shot peening | |

| Durability | Dynamic Max. 2 million loading cycles | ||

| Material | SUP10(Correspond to 51CrV4,6150) Chrome-Vanadium steel for spring(Correspond to ISO 683-14 51CrV4) | Wire diameter: φ13∼25 Material length: 8 m | |

| Wire diameter: φ26∼90 Material length: 12m | |||

| Conditions of use | Indoor working temperature | -50∼180℃ *3 | |

| Rustproofing | Standard | Coated with anti-rust oil | |

| Coated with black powder (Polyester resin) | |||

| Electrodeposited black coating | |||

| Dacrotized finish | |||

| Disgo plating | |||

| Other | |||

| Customspecifications | Material | Specifications by material | SUP10, Wire diameter: φ26∼90, Material length: 14.7 m |

| Durability | Material surface improvement | Hot-rolled skin removal | |

- *1:Product allowable stress varies according to temperature. For more information, speak with a Tokai Spring industries engineer.