Spring Design

Design information for engineers, such as spring calculation formulas,

which are the basis of spring design, can be found here.

- Tokai Spring HOME

- Spring Design

- Friction Springs: Calculation Formulas

Friction

Springs

Meaning of Symbols

The symbols used for spring design are shown in Table 1 below. The values of the longitudinal elastic modulus (E) are based on Table 2.

Table 1. Symbols and units used in calculations

| Symbol | Meaning of Symbol | Unit |

|---|---|---|

| Ac | Cross-sectional area of the outer ring | |

| Ai | ||

| rc | Center of gravity radius of outer ring cross-section | |

| ri | Radius of center of gravity of the inner ring cross-section | |

| a | Angle of contact surface | |

| ρ | Friction angle | |

| δ | Spring deflection | mm |

| c | Spring index c=D/d | — |

| n | Number of contact surfaces | |

| R1 | Spring constant when pressurizing | |

| R2 | Spring constant when decompressing | |

| E | Longitudinal elastic modulus | N/mm2 |

Table 2.Longitudinal elastic modulus:E(N/m㎡)

| Material | E Value | |

|---|---|---|

| Spring steel material | 206×103 | |

| Stainless steel |

SUS302 SUS304(Correspond to X5CrNi18-9,1.4301,S30400) SUS631(Correspond to X7CrNiAl17-7,1.4568,S17700) |

186×103 186×103 196×103 |

Spring Constant and Load

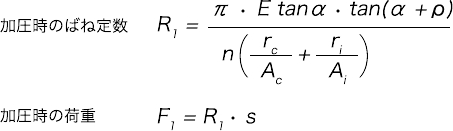

The basic formula for the spring constant and load at the time of pressurization are calculated with

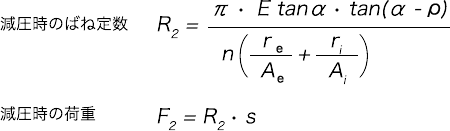

The basic formula for the spring constant and load during decompression can be calculated as follows.