Custom Springs

We are ready to take on any challenge!

From large springs to small springs, here we introduce our springs that never fail to live up to expectations.

- Tokai Spring HOME

- Custom Springs

- Flat Springs

Flat Springs

They are not just waves, they have various characteristics.

The precision needed requires delicate craftsmanship

Features Of Our Springs

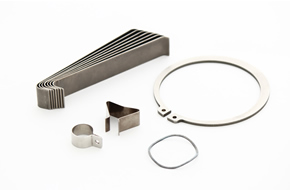

Flat springs (leaf springs) are also called elliptical springs or cart springs, and all plate-shaped springs are basically classified as flat springs. Therefore, flat springs come in various different shapes, and so it is necessary to evaluate the stress consistently for each product in its design. Flat springs are also used for a wide range of applications, such as packing in high-temperature atmospheres and complicated structures such as wristwatches. At Tokai Spring we can support not only thin plates but also materials with a plate thickness of over 30 mm.

Complex shapes can be custom-made

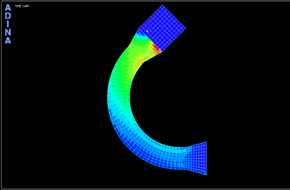

We provide flat springs that satisfy the desired shape and load characteristics by drawing and materializing complicated shapes even from abstract illustrations. Also, for complicated shapes for which it is difficult to conduct durability evaluations, using FEM analysis has made conducting highly accurate durability evaluations possible

Key Points on Our Devotion to Handmade Springs

When you hear the name flat springs, you may think of springs with simple abilities to simply hold things down, but we can manufacture heat-resistant springs and corrosion-resistant springs that can withstand a variety of severe usage environments. By designing flat springs with a focus on functionality and supporting small-volume production, we also bring to life flat springs that clients truly seek.

Features of Tokai Spring’s flat springs

A wide variety of materials

We have a large selection of materials suitable for a variety of environments, including cryogenic environments of -273°C, high-temperature environments of 600°C, and corrosive environments. With these abundant material capabilities, we are able to manufacture a wide variety of leaf springs to meet our customers’ requirements.

Facilities for flat springs

We have a variety of equipment and tools to realize all kinds of leaf springs with high precision. We have precision shearing to cut out the exact material length, dies and jigs to create the ideal spring shape, general-purpose milling machines suitable for high-mix low-volume production, roll benders to freely create R-curved surfaces one by one, vacuum heat treatment to minimize oxidation and decarburization, load measuring machines developed in-house exclusively for springs, 3D measuring machines to accurately evaluate the shape, and our own equipment and know-how to realize the springs that our customers demand. Our original equipment and know-how enable us to produce the springs that our customers demand.

Craftsmen of flat springs

Craftsmen of Tokai Spring Industry think and create all kinds of tools and jigs by themselves. We will do our utmost to solve even the most difficult problems with our unique handmade concept of handcrafting, which includes the consideration and fabrication of special molds that take into account the characteristics of the materials and the particular shape of the molds. This is the craftsmanship of Tokai Spring Industry.

-

- We support design and production even for small lots of one or two springs

- In the spring industry, our “complete custom-made production & high-mix, low-volume manufacturing” is an extremely unique production system which has not changed since our founding.

We guarantee to deliver the quantity you need, when you need it, at high quality.

-

- We support all kinds of environments with the likes of heat resistance, corrosion resistance, and durability

- Springs are very sensitive to high and low temperatures and corrosive atmospheres such as rust. Tokai Spring conducts daily verification tests to properly maintain the performance of our springs in any environment such as at temperatures of 100°C or higher, -20°C or lower, as well as for applications in which our springs are exposed to seawater or industrial water!